Specification parameters

| Type | BL-3D-81000 Parameter | |

| Applicable Wire Dia. | Soft material Φ:3.0-10.0mm Hard material Φ:3.0-8.0mm | |

| Bending stroke | 850mm | |

| Number of control Axis | 8 Axis | |

| Total power | 20.6KW | |

| Power Of wire turning Motor | 2.7KW | |

| Power of wire feeding motor | 5.5KW | |

| Power Of Angle control Motor | 2.0KW | |

| Inner/outer angle motor power | 2.7KW/2.7KW | |

| Power of the lifting motor for the pallet | 1.0KW | |

| Power Of Wire Cuter Motor | 2.0KW | |

| Left and right translation motor power | 2.0KW | |

| Maximum wire feeding speed | 40m/min | |

| 300mm±0.1mm | ||

| Angle accuracy | 90°±0.1mm | |

| Input Power | 380V/50Hz/3Ph | |

| Machine Size(L*W*H) | 3800KG | |

| Machine Size(L*W*H) | 4420mm*2100mm*1600mm | |

| Automatic feeder | Maximum load Weight: | 1500KG |

| Size (L*W*H) | 2100mm*2100mm*1300mm | |

Characteristic description

1. Adopting a computer control system and imported servo motors.

2. The computer has a Chinese and English (optional) interface, easy to operate, accurate positioning, and all motors can run synchronously or separately.

3. When wireless, disconnected, or tangled, there is an automatic shutdown design and automatic acceleration function of the wire rack, making production easier and more effective.

4. The machinery is equipped with automatic lubrication and oil supply design, ensuring the long-term operation of the equipment.

5. The device has bending and translation functions, which can shape most difficult 3D products and switch between multiple different R angles.

6. Suitable for production: wire formed products such as automotive parts, daily hardware, computer appliances, mechanical hardware, etc. From a product structure perspective, it is more suitable for producing frame products, and the flat support is more stable.

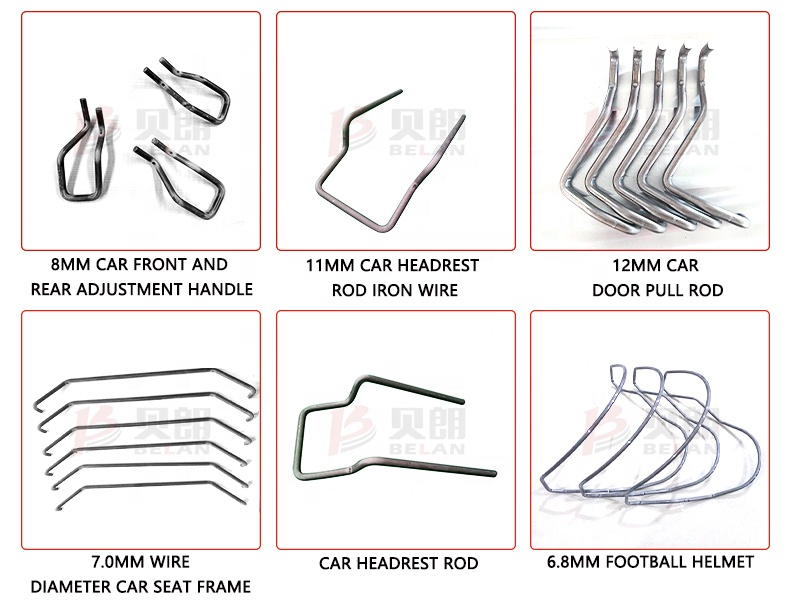

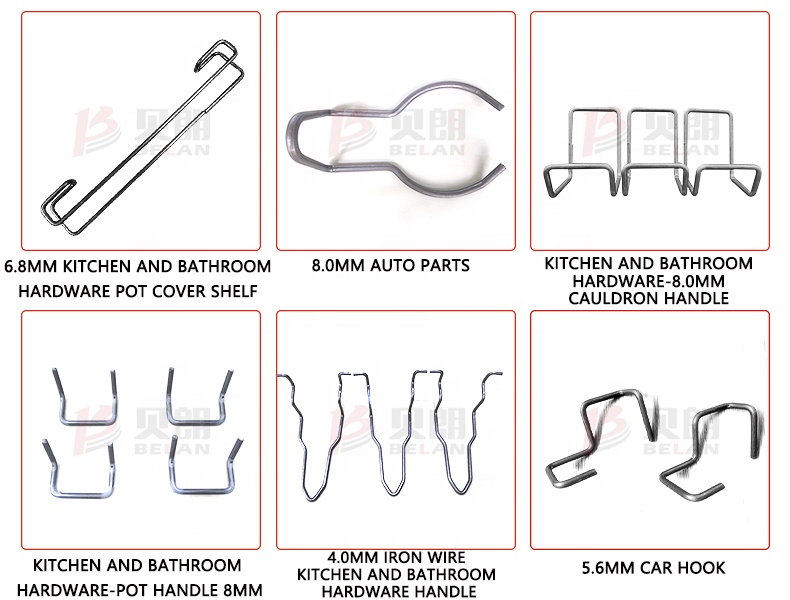

Sample image display

Suitable for production: car seat frames, sunshade frames, car door lock rods, handicraft metal wires, kitchen utensils and tableware brackets, storage cages, supermarket trolleys, supermarket shelves and other wire shaped products